We live in a material world. Modern industries are demanding more from materials than ever before. With advances in artificial intelligence, robotics, automation, and a move toward low-volume, high-value products, the way we process and create consumer goods is evolving.

Research and educational programs at U of T Engineering are creating next-generation technology for advanced manufacturing while preparing future engineers to lead in industry. We are developing more efficient processes for extracting resources, customizing the design of materials and processes, and optimizing distribution networks for large, complex operations. These insights impact every stage of the manufacturing value chain.

Manufacturing remains one of the key drivers of the economy — in Ontario, Canada and around the world. By enabling industry to do more with less, our advanced manufacturing experts are enhancing global prosperity, reducing our environmental impact and improving quality of life.

RESEARCH CENTRES & INSTITUTES

-

2014: Toronto Institute of Advanced Manufacturing (TIAM)

TIAM expedites the research and development of advanced manufacturing technologies by creating a multidisciplinary network focused on sharing knowledge, ideas and resources. The Institute is a global leader in translating lab-based technologies into scaled-up processes and by contributing to the education of highly qualified personnel in the manufacturing sector. Learn more about TIAM.

-

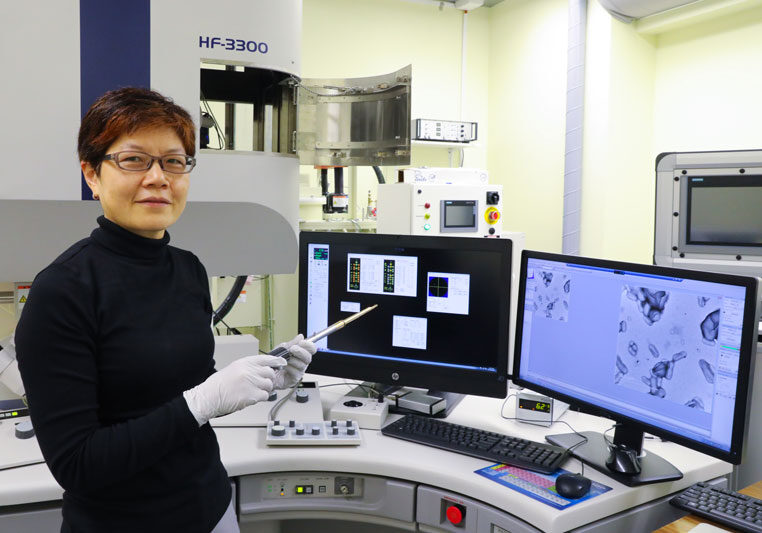

2012: Ontario Centre for the Characterization of Advanced Material (OCCAM)

This multidisciplinary facility provides leading-edge equipment — including electron microscopes and mass spectrometers — and expertise in the imaging, analysis and manipulation of materials at the nanometre scale. OCCAM was created with strategic investments from the Canada Foundation for Innovation (CFI), the Ontario Ministry of Research and Innovation (MRI), and Hitachi High-Technologies Canada. Learn more about OCCAM.

-

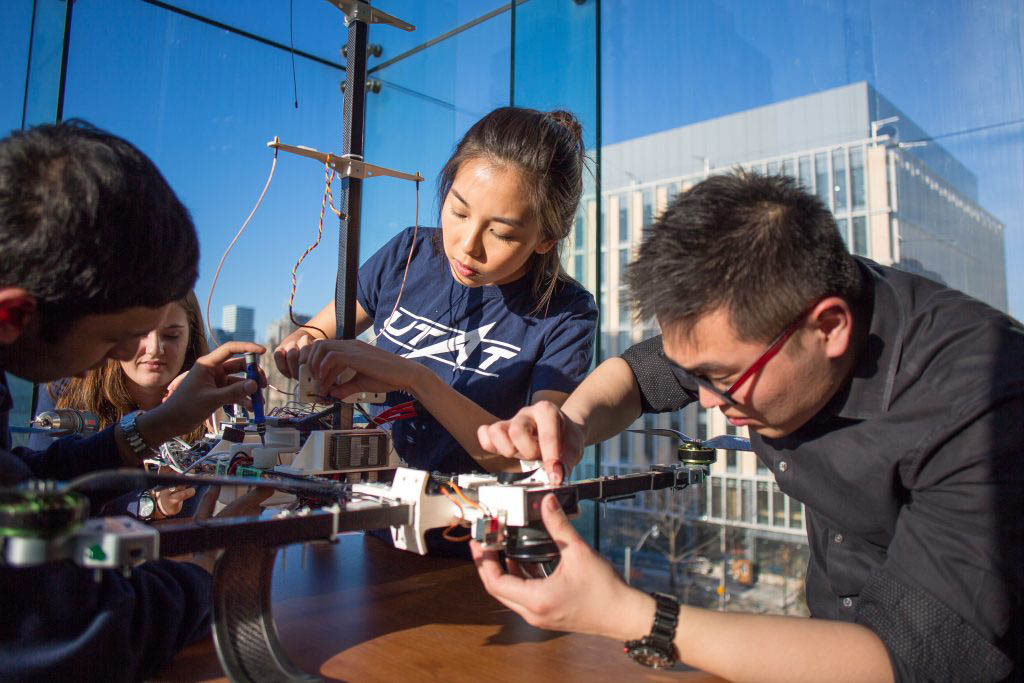

2010: Institute for Robotics & Mechatronics (IRM)

IRM brings together more than 50 principal investigators from across U of T Engineering and the Department of Computer Science to create the next generation of intelligent and autonomous robots for use in a variety of sectors: manufacturing, exploration, rescue, security and more. Learn more about IRM.

-

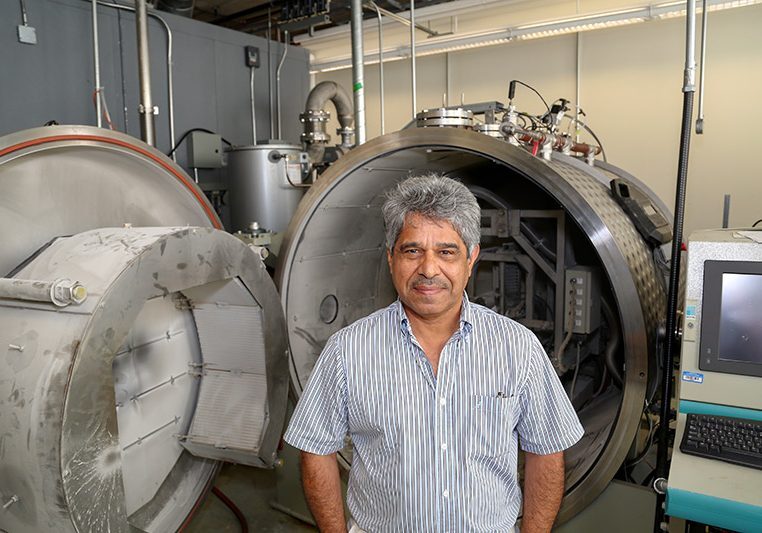

1998: Centre for Advanced Coating Technologies (CACT)

A collaboration between the Departments of Mechanical & Industrial Engineering and Materials Science & Engineering, CACT conducts fundamental research in the area of thermal spray coating. It contains facilities for atmospheric plasma spray (APS), high velocity oxy-fuel spray (HVOF), wire-arc spray, and radio-frequency inductively coupled plasma (RF-ICP) and vacuum plasma spray forming (VPSF). Industrial collaborators include BMW USA, Pratt & Whitney Canada, TeckCominco and the National Research Council’s Industrial Materials Institute.

EXPERTISE

Selected areas of expertise in advanced manufacturing research at U of T Engineering

- Advanced Aerospace Structures

- Advanced Coating Technologies

- Cellular Hybrid Materials

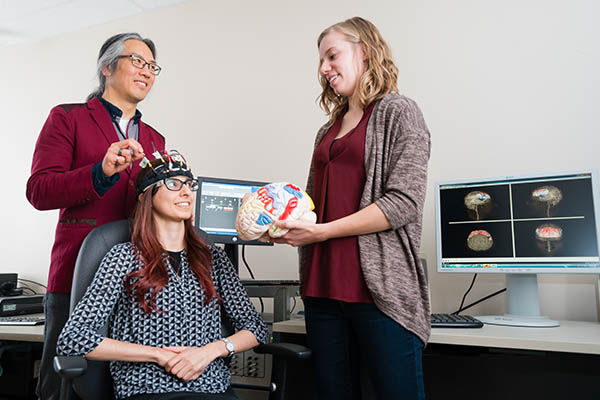

- Human-Machine Interaction

- Intelligent Decision Engineering

- Laser Photonics Fabrication

- Maintenance Optimization & Reliability Engineering

- Microcellular Plastics

- Multifunctional Lightweight Structures

- Nanomaterials

- Organic Optoelectronics

- Robotics & Automation

- Smart & Multifunctional Materials

RESEARCH IMPACT

Recovering rare-earth elements from e-waste

A retired smartphone languishing in a drawer may seem worthless but, from a materials point, it is a gold mine. Jointly appointed to the Departments of Chemical Engineering & Applied Chemistry and Materials Science & Engineering, Professor GISELE AZIMI (left) and her team are developing new methods for recovering strategic materials — including rare-earth elements — from disused electronics and other forms of waste.

Rare-earth elements are used in magnets and batteries, and growing demand for both consumer electronics and electric vehicles is causing prices to rise faster than new mines can be developed to supply them. Now various industries are looking at non-traditional sources for these materials.

Azimi and her team are working with Nutrien, a major global producer of fertilizer, to develop techniques for extracting rare-earth elements from an industrial byproduct called phosphogypsum. They have also partnered with Rio Tinto Alcan to harvest rare-earth elements from a byproduct of the aluminum industry known as ‘red mud.’

Current recycling techniques are energy-intensive. Azimi and her team have a different approach which can recover up to 90 per cent of the rare-earth elements contained in a nickel-metal-hydride battery. Future work will focus on growing this process from the lab to the industrial scale.

Through various projects, Azimi has also partnered with Tenova Goodfellow, Hatch, Potent Group, Mercedes Benz Research and Development North America, and H.C. Starck. In the past, she has also worked with Agrium, Vale, and GreenMantra Technologies.

Tiny features, big challenges

For nearly 30 years, a partnership between Hitachi High-Technologies Canada (HHTC) and U of T Engineering has enabled advanced analysis of a wide range of samples — everything from volcanic glass from the bottom of the ocean to rocks that the Apollo astronauts brought back from the moon.

HHTC designs and deploys electron microscopes, and some of their most advanced equipment is at the Ontario Centre for the Characterisation of Advanced Materials (OCCAM). This interdisciplinary research centre, co-located in the Departments of Material Science & Engineering and Chemical Engineering and Applied Chemistry, is built around state-of-the-art electron microscopy and surface characterization tools.

Involving both equipment and personnel, the partnership enables HHTC to draw on the practical challenges that users are trying to address to catalyze the development of new microscopy technologies. OCCAM is the first place that these technologies are deployed, and the two-way partnership continuously yields new protocols and procedures. By remaining at the forefront of electron microscopy, OCCAM enables its users — from across the Faculty and beyond — gain insight into the natural world and design better devices, from dental implants to microchips, solar cells, aircraft and much more.

Building the bark biorefinery

With 347 million hectares of forest land — about nine per cent of the world’s total — Canada is a leader in the global forest products industry, from softwood lumber to newsprint. But many parts of the tree, such as the bark, are not currently used for any product; they are either burned for energy or discarded.

Chemical engineering professor NING YAN, an expert on the chemistry of wood and bark, hopes to change that. Her research focuses on developing sustainable bio-based chemicals and materials using renewable forest biomaterials as feedstock. The resulting materials would be greener than the current options, which are produced using fossil fuel-based processes.

In partnership with forest, agriculture, chemical, materials and automotive companies, Yan’s lab is working to extract and convert forestry and agriculture residues to feedstock for the synthesis of several sustainable materials. In turn, these materials — which include adhesives, resins, polyols and light-weight engineered composites — generate higher economic value for the forest and agriculture sectors.

FPInnovations, Woodbridge Foam, Arclin, Huntsman Corporation, Resolute Forest Products and Tembec are among Yan’s ongoing industry partnerships. She believes that strong partnerships with industry are critical to the success of her research — they catalyze the development of bio-based products and technologies that meet industrial application needs. These partnerships have also allowed her graduate students and post-doctoral fellows to contribute solutions to challenges faced by industry.

The impact of advanced coating technology: From aerospace to health care

Today’s airplanes have the capability to fly nonstop from Toronto to Hong Kong — something unheard of 20 years ago. The reason for the improvement in fuel efficiency has a lot to do with advanced thermal-barrier coating technology, which allows engines to run at higher temperatures, resulting in better fuel efficiency.

Mechanical engineering professor JAVAD MOSTAGHIMI is improving and innovating coating technology, and is working alongside 10 companies, including Airbus Industries, Pratt & Whitney Canada, Bombardier and Liburdi, to improve fuel efficiency and advance the aerospace industry for years to come.

Mostaghimi, a Distinguished Professor in Plasma Engineering and founding Director of the Centre for Advanced Coating Technologies (CACT), is also applying his research to the health-care sector. The World Health Organization (WHO) has recognized health-care-associated infection as a major patient safety issue for developing countries, affecting hundreds of millions of people worldwide. In developing countries, the risk is up to 20 times higher than in industrialized countries.

Mostaghimi and his team have developed a simple and affordable antimicrobial copper coating technology to help combat the global challenge of hospital-associated infections. At the Hospital Nacional Cayetano Heredia in Lima, Peru, Mostaghimi has tested the effectiveness of copper coating on furniture in an outpatient clinic room and on other commonly touched surfaces to improve patient safety.

“Our research and educational programs cover the entire manufacturing sector, from engineering to management to logistics. Our goal is to enable existing companies to innovate and improve, and to support the development of new businesses that don’t exist today.”

PROFESSOR HANI NAGUIB

Director, Toronto Institute of Advanced Manufacturing (TIAM)

THE FUTURE OF ADVANCED MANUFACTURING

Factory of the Future

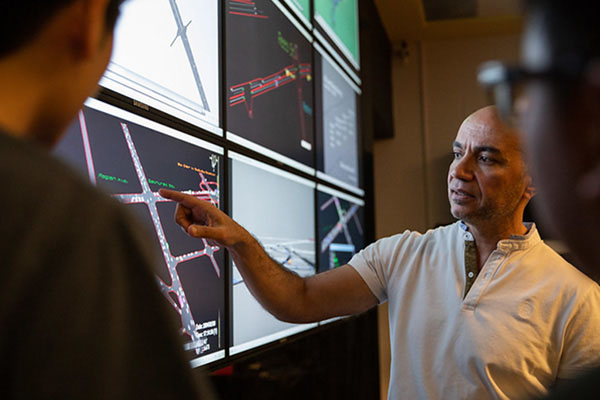

Led by mechanical and industrial engineering professors HANI NAGUIB, GOLDIE NEJAT and CHRISTOPHER BECK, the Factory of the Future initiative will transform smart manufacturing by preparing leaders of tomorrow and enabling new product development.

The Factory of the Future will undertake projects across three strategic focus areas: robotics and automation, smart sensing systems, and human-machine collaboration. State-of-the-art labs in the Toronto Institute of Advanced Manufacturing (TIAM) and the University of Toronto Robotics Institute (formerly the Institute for Robotics & Mechatronics) will enable partner companies to collaborate and develop new technologies and processes. These processes will be piloted within an industry environment to determine feasibility across design, assembly, maintenance, repair and inspection functions.

Ultimately, the Factory of the Future will deliver manufacturing solutions that benefit industry and society at large while keeping the Canadian manufacturing industry and workforce globally competitive.

Bombardier invests in Toronto aerospace hub

Canadian aerospace giant Bombardier Inc. is helping to establish an aerospace research hub near Downsview Airport, in collaboration with the University of Toronto Institute for Aerospace Studies (UTIAS) and other local academic institutions.

The company will invest $1.5 million over five years to fund core research that is part of a consortium of industry and academic partners, including U of T, called the Downsview Aerospace & Innovation Research (DAIR). Starting in 2019, Bombardier is also investing $1 million over five years to set up new research centres at U of T and Ryerson University that will focus on acoustics and advanced interiors, respectively.

Continuing its longstanding industrial partnership with Bombardier, UTIAS is poised to lead new research initiatives through grants that support academic-industry collaboration. Professor PHILIPPE LAVOIE, an expert in turbulence and aerodynamics, is one of two U of T researchers who will work on noise reduction with Bombardier as part of the new UTIAS research centre.

SPECIALIZED EDUCATIONAL OFFERINGS IN ADVANCED MANUFACTURING

Our Master of Engineering students can choose from a wide range of technical emphases including Advanced Manufacturing, while all engineering graduate students have the option of pursuing a Robotics & Mechatronics emphasis. Undergraduates in the Engineering Science program can major in Robotics, while students in our core engineering disciplines can pursue minors in Advanced Manufacturing and Robotics.

LATEST ADVANCED MANUFACTURING STORIES

OUR INNOVATION CLUSTERS

U of T Engineering has the breadth and depth of research excellence as well as the capacity to effect global change across these key domains.

OUR EXPERTS

Find the U of T Engineering researchers with the expertise to solve your most complex challenges

LEADING INNOVATION STARTS HERE

DOWNLOAD PDF

Connect with us to discuss how a partnership with U of T Engineering can benefit your organization.